In our previous blog article, we discussed what tests should be applied to Battery Energy Storage Systems (BESS) during factory acceptance tests (FATs) and site acceptance tests (SATs). But how do we assess a BESS from a technology and configuration standpoint to ensure that it matches current sector parameters and features in terms of performance and safety?

This is where current standards come into play. As we mentioned before, standards organisations work tirelessly to keep up with advances in lithium-based battery and BESS technologies, so the use of these guidelines and/or specifications – created by globally recognised experts and authorities in the sector – is essential. This article maps out the relevant standards that apply to a BESS.

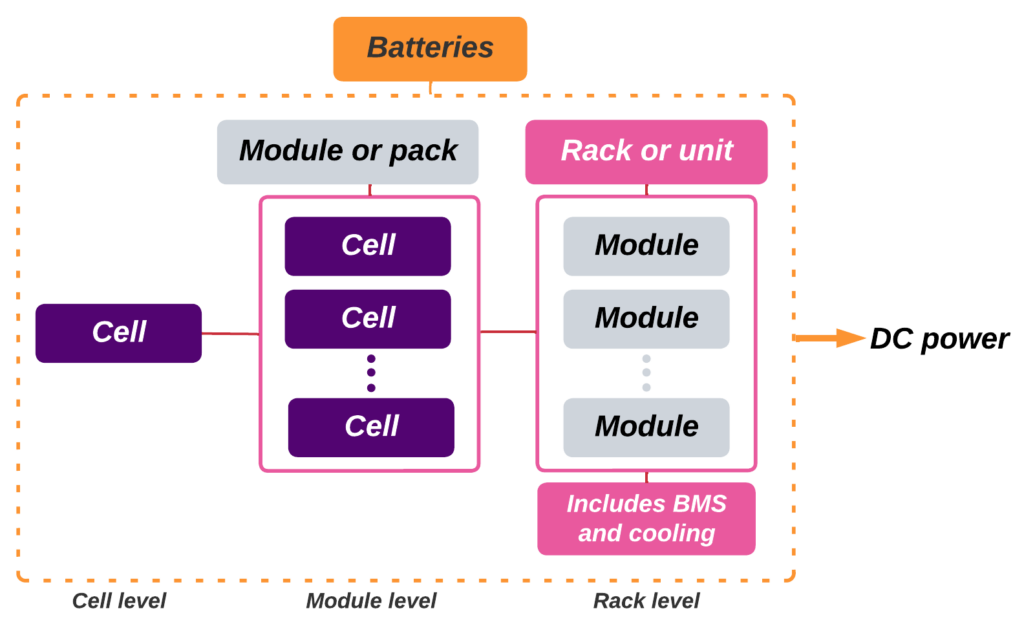

When we talk about standards, the key is understanding that a BESS is a whole comprised of the sum of its parts. Thus, by turning a BESS upside down and starting from its smallest part, we get the following:

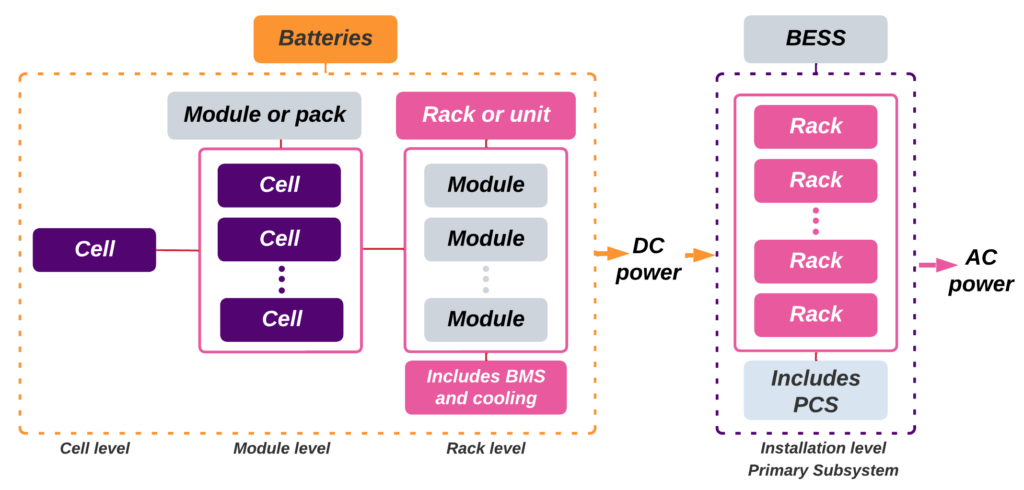

A cell, module, or rack capable of storing DC energy is the reservoir part of a battery storage plant, equivalent to the water in a hydropower plant. A power conversion system is required to turn this stored energy into power, like the turbine in a hydropower plant.

For BESS, the power conversion system (PCS) is an inverter (a power electronic device) that turns the batteries' DC power into AC power. Please note that there is a slight difference between the power conversion system and the power conditioning system across different standards, but we will leave that explanation for another discussion. In this article, we refer to PCS as the inverter.

Everything before the PCS is then “a battery.” Usually, the batteries’ energy capacity is described in terms of Watt-hours, because Energy = Power × Time. Downstream from the inverter (or PCS), it transforms into Watts, because Power = Energy/Time.

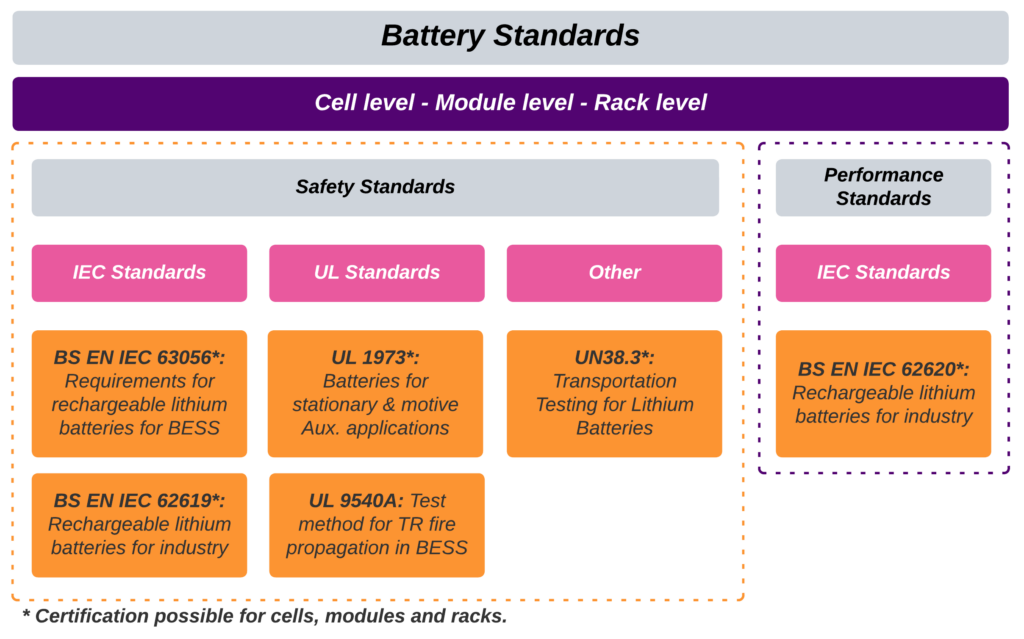

Batteries have specific minimum performance and safety requirements laid out by the standards we mentioned earlier. Standards at battery level usually discern between the cell, the module and the rack. For the standards on which a battery can be certified, this differentiation is stated. Usually, compliance with battery standards at cell, module and rack levels (as shown in Figure 1) is required.

At Blanboz, we consider that standards for BESS are generally divided into two distinct categories:

Underwriters Laboratory (UL) is based in the U.S. and is completely authorised and approved by the Occupational Safety and Health Administration (OSHA) to write safety standards. Some of its standards are fundamental to BESS and are widely requested and recognised in the sector. Meanwhile, the standards-writing International Electrotechnical Commission (IEC) is based in Geneva, Switzerland, and is closely related to the International Standards Organization (ISO). IEC standards are international and based on contributions from basically every country worldwide, which means that their publications and guidelines are always vital.

At Blanboz, we consider UL 19732 the most comprehensive safety standard for batteries in a BESS, together with its IEC counterpart, IEC 62619.3 Both of these standards are widely adopted within the sector. We normally expect that the batteries on a BESS are certified to both UL and IEC standards at cell, module and rack levels.

It is worth noting that one of the first widely adopted lithium battery standards in the industry was UL 1642,4 but for BESS nowadays this standard is included and expanded in UL 1973. It is still quite common to find batteries certified to this standard in the industry as part of UL 1973 certification; however, UL 1642 by itself is a basic standard and lacks the completeness of UL 1973.

Additionally, for BESS the IEC 62619 standard is accompanied by the IEC 630565 standard. This is a relatively short standard of only 24 pages, under the umbrella of IEC 62619, and expands on the test requirements necessary for batteries used in a BESS. At Blanboz, we encourage users to follow this standard as well as IEC 62619. However, we understand that it is not currently widely adopted within the industry.

One of the main risks of lithium batteries is that if the temperature of the cells is not adequately controlled, it may start increasing uncontrollably in a chain reaction known as thermal runaway (TR). TR always starts at a cell level, but resources for its management and containment should occur at all levels of a BESS. This is where the UL 9540A6 test methodology comes in. Please note that UL 9540A is commonly but mistakenly believed to be a standard; it is only a test methodology. It originates from the UL 95407 standard, which is a safety standard for BESS (by which we mean the whole system, not just batteries!). The purpose of UL 9540A is to establish a test methodology to look for possible stimuli for TR at the cell level and to assess prevention and containment of the fire, or in other words evaluate fire propagation, at the module, rack and system levels. The methodology thus assesses the hazard management strategies of the system to mitigate the causes and consequences of TR. We expect various tests based on UL 9540A to be performed at several levels of a BESS.

Another common safety requirement for batteries is the transportation standard elaborated by the United Nations. It is contained in their Manual of Tests and Criteria, part III: Classification procedures, test methods and criteria relating to various hazard classes, Section 38.3: Lithium metal and lithium-ion batteries. It is commonly known simply as UN38.3.8 Batteries can be tested and certified to this standard from the cell up to the module level, to guarantee their safety during transportation.

Moving on from safety, when it comes to standards to assess the performance of lithium-based batteries for BESS usage we at Blanboz use IEC 626209 as our main reference. Check our previous blog article for a glimpse of our approach to battery performance testing or contact us for support!

See Figure 2 for an overview of the main standards for batteries for lithium-based BESS.

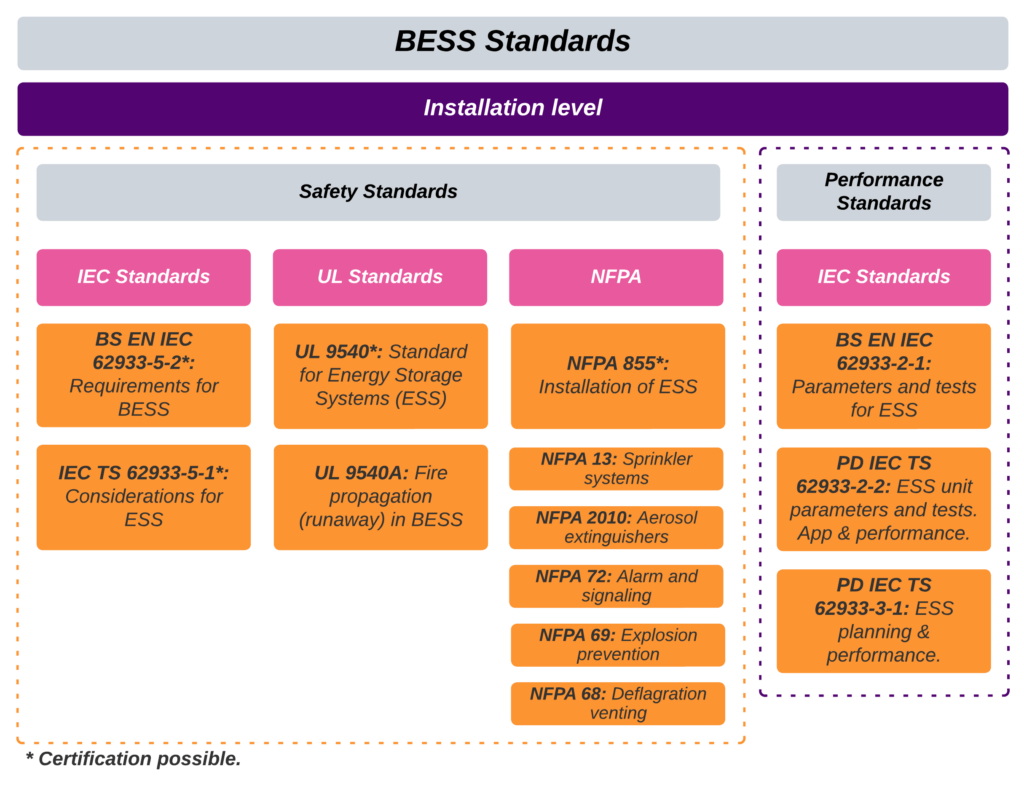

With the standards we identified and explained above, we can comprehensively assess the batteries of a BESS. However, when we get to the system or installation level, new subjects raise their heads. As shown in Figure 3, when we join the batteries with a PCS and start generating AC power, we have a BESS.10 Using IEC standards nomenclature, the combination of the batteries with the PCS is referred to as the primary subsystem.

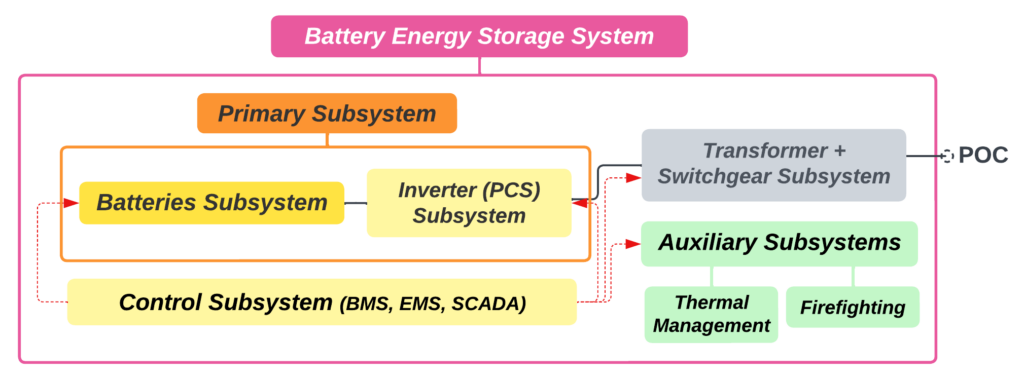

Besides the above established primary subsystem, a BESS also has:

Sometimes the transformer and switchgear subsystem, which is the connection subsystem, is not considered. Both iterations are correct and either can be considered a BESS. See Figure 4 for the main components of a BESS.

With that in mind, each of these subsystems has standards that establish their desired characteristics; again, these standards are separated into safety and performance requirements. These specific standards are not covered in this article; however, the essential ones are referenced in the standards we will mention below.

At Blanboz, we consider the most comprehensive safety standards for BESS to be UL 9540, including its offspring test method UL 9540A, and its IEC counterpart IEC 62933-5-2,11 which acts in concert with IEC 62933-5-112. Notice from their titles that these standards are for any complete energy storage system (ESS), not only lithium-based ESS. They additionally consider the PCS, the communication system, the system enclosure, and the fire strategy (detection, suppression, explosion protection, and propagation) among other characteristics of complete installations. These standards compile all the minimum safety requirements for a BESS and make specific references to other required standards.

One thing we notice is that because UL 9540A focuses on the propagation of fire due to cell-level thermal runaway, this standard test method is always associated with batteries. In fact, it is an ESS standard that covers all the levels up to the installation level. Furthermore, this test method aims to assess the temperature, released gases and containment measures at everything from the battery level to the installation level. The standard evaluates the effectiveness of the sprinkler system and the fire protection plan for the entire BESS. Currently, assessment based on this standard is the industry's default setting, although the standard is not technically mandatory.

Additionally, the IEC 62933-5-2 and 62933-5-1 standards act as comprehensive standards (or guidelines), but due to the interlaced relationship between the NFPA and UL standards the IEC standards are not commonly encountered or widely adopted in the industry.

Having just mentioned NFPA standards, we should explain what they are. The National Fire Protection Association is a U.S.-based standards organisation focused on fire prevention and mitigation. When it comes to BESS, its standards are completely recognised and adopted by the industry. A completely fireproof BESS must have fire prevention, suppression, and explosion prevention capabilities. These properties are detailed in the following NFPA standards:

NFPA 13: 2019 Standard for the Installation of Sprinkler Systems

NFPA 2010: 2019 Standard for Fixed Aerosol Fire-Extinguishing Systems

NFPA 72: 2018 National Fire Alarm and Signalling Code

NFPA 69: 2018 Standards on Explosion Prevention Systems

NFPA 68: 2018 Standard on Explosion Protection by Deflagration Venting

The specific firefighting requirements for BESS are summarised in what we consider the most comprehensive guideline for fire management best practices, the NFPA 85513 standard, which is a complete and detailed compilation of fire safety requirements for BESS. It is closely related to BESS UL standards, as their requirements intertwine. Because fire is always a crucial concern with BESS, we always recommend full compliance with NFPA 855 and related standards.

NFPA 855 standards are the minimum requirements for hazard mitigation regarding fire whereas UL 9540 is an overall compatibility and safety standard. Both of these standards are for all types of ESS and include electrochemical-based energy storage systems (BESS).

Chapter 4 of the 2023 version of NFPA 855 declares that storage systems must be formally evaluated (listed) in accordance with UL 9540. This requirement is also present in the 2020 version of the NFPA 855 standard.

Additionally, Annex A of the 2023 version of NFPA 855 basically states that an equivalent or superior system or method regarding safety may be used to assess a storage system. We will provide further analysis and a comparison between UL 9540 and its IEC counterparts regarding equivalency or superiority in terms of safety in a future blog article. Currently, NFPA 855 does not explicitly mention any other organisation’s equivalent safety standard to UL 9540.

Finally, NFPA 855: 2023 mentions that existing lithium-ion ESS that are not UL 9540 listed require their hazard mitigation analysis (HMA) to be reviewed by project-specific competent authorities. Conducting an HMA is always considered an industry best practice. If you need assistance creating a hazard mitigation analysis or have any concern related to the safety compliance of your BESS do not hesitate to contact us.

For performance, the tables turn and IEC standards become the go-to reference for assessing the functioning and performance capabilities of your installation. The main performance assessment standard for a BESS is IEC 62933-2-114. It reigns supreme because all measurements of active power, reactive power, energy capacity and round-trip efficiency, among other performance measurements, are well defined in it.

This standard is accompanied by the technical specifications IEC TS 62933-2-215 and IEC TS 62933-3-116, which further detail and specify performance tests for a BESS in different scenarios.

Finally, we refuse to end this article without mentioning that, even though there is no current standard that deals with the performance of a BESS’s thermal management system either with HVAC and/or liquid-cooling that we are aware of, this is one of the main topics, if not the main topic to address when assessing BESS performance. We agree with the famous tech YouTuber Marques Brownlee: “What ruins your battery is heat.”17 Consequently, we consider that a thorough evaluation of the BESS cooling system at the cell level using computational fluid dynamics (CFD) and/or real-world testing should be performed to guarantee that cell temperature does not increase above the recommended limits. We expect that in the future, all BESS manufacturing companies should show their detailed heat management data for clients to review.

Figure 5 shows an overview of Installation-level standards for BESS. If you need further assistance with a technology review, technical due diligence, or the creation of a technical employer’s requirement, at Blanboz we can help you!

Finally, when we specifically need to assess the safety characteristics of a PCS, we can do so easily because it is a mature and well-standardised piece of equipment (thanks to the solar photovoltaic industry, among others). Accordingly, we look for evaluations and/or certifications on UL 174118, including its supplement B (UL 1741 SB), and/or IEC 62109-119 and IEC 62109-220. These are safety standards and cover the device’s construction requirements and the applicable tests to be performed on it. They are therefore widely used in the industry. Because the PCS serves as the interface between the batteries and the grid, converting DC power to AC power and vice versa, and/or setting electrical parameters such as voltage and frequency, the assessment of its performance and capabilities is included in the testing of the BESS as a complete system and is detailed in the IEC 62933 family of standards.

Tomas Gomez – Guest, Mechanical Engineer with more than 13 years of experience in oil & gas project construction. Eager about my newfound purpose: helping with the transition to clean energy and decarbonising through quality engineering. https://www.linkedin.com/in/gomeztag/

Andres Blanco – Project Consultant | Managing Director at Blanboz, an engineer with almost 15 years of experience in the renewable energy field, with the last seven to eight of these years fully dedicated to BESS through the full project life cycle. Electricity for all - Batteries lead the charge. Further information at www.blanboz.com , if you want to contact me, please do so at a.blanco@blanboz.com , www.linkedin.com/in/andresblanco77